The Optimized Land Fill Sequence Plans

-Will your current lined area last until next year?

-Are your access roads, stockpiles and haul roads in the best location for the longest use?

Landfill sequence plans provide answers to these and other questions. They do more than just show an arbitrary sequence of filling - they show an "optimized" operation. Optimizing a site's sequence plans insures that the overall operation is as productive and cost-effective as possible. An optimized sequence plan also provides the basis for budgeting and scheduling major landfill projects. Quantifying and insuring adequate filling capacity - especially during wet weather - is included as well.

There are many things to consider when determining the optimized filling sequence for a landfill. There is no universal equation that shows how to sequence phases. Sequencing is based on a combination of economics, aesthetics, and practical judgement in regards to access, drainage, leachate control, and minimized soil handling.

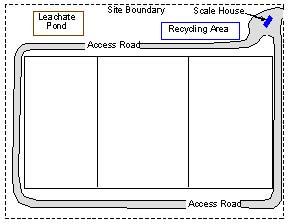

Base grade plan

Planning Period

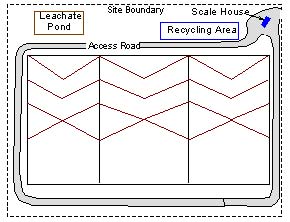

Optimized fill sequence

Developing an optimized set of landfill sequence plans requires a two-step approach. First, we identify where the site headed in the long term. This information is included in the long-term landfill sequence plan. Second, we identify in detail what will be done in the short-term to reach the long-term goals. This information is provided by a detailed annual access plan.

Both the long-term and short-term plans consider five main areas of operations, however the short-term plan allows for more detailed planning like placement of tipping pads and soil stockpiles.

Each of the five main areas which are addressed in the fill sequence plan will receive varying amounts of detail, depending on the site conditions. These five main areas include:

-Economics

-Access

-Drainage

-Excavation

-Filling

Economics

Economy of Scale

With most types of construction projects there is an economy of scale - the larger the project, the lower the unit price to construct. Some of the savings is based on the increased competition for a larger job; some is based on the contractor begin able to amortize his mobilization and demobilization costs over a larger project. From this standpoint, it would appear that the larger the construction, project, the better. The other side of the coin is the time value of money.

Time Value of Money

Delaying the more costly phases is in accordance with the basic economic principle that there is a time value of money due to compounding interest. In other words, present dollars are more valuable than future dollars. Thus, it is usually best not to spend money until you have to. An optimized long-term fill sequence plan reflects this basic economic principle.

Access

Refuse Vehicle Roads

Because access roads are costly to construct and maintain, it is usually best to build them sparingly and place them in a location where they will be useful for as long as possible. This is part of the planning process, and an optimized set of fill sequence plans will take access roads into account.

Drainage

No matter what part of the landfill you are working on, it must drain properly. This means water must be collected and handled efficiently without eroding or weakening other structures - all at the lowest cost. When preparing drainage plans, we prefer to work backwards, from the final (end of site) development plan to the present. This insures that the interim drainage structures we build today, will work toward and connect to the final, permanent structures for the site.

Excavation

Soil Handling

The first rule of soil handling is to move it once and move it fast. Double-handling should be avoided while excavating. Obviously, some initial excavation is required before garbage can be placed. In order to minimize up-front costs, however, the initial excavation should be minimized as much as possible. If the soil excavated initially is to be used later on for cover, the double-handling costs should be minimized as well. This can be accomplished with careful planning and incorporated into an optimized fill sequence plan.

Excavation Sequence

Excavating soil, like other landfill tasks will be performed continually throughout the life of the site. Many landfills will excavate millions of cubic yards of soil. Obviously, with projects of this size, efficiency is important. Like the other components of the sequencing plans, the excavation plan is based on the "optimum" methods determined as part of the operations plans.

In order to minimize excavation costs, every haul road should be designed to provide the quickest possible cycle times. Because of the time value of money, the best way to sequence the excavation is to make the shortest cycles first, postponing the longer cycle times until later.

Filling

Effect on Cost

The fill sequencing of any landfill will have a major effect on the overall cost of the site. In general, fill sequencing that provides the most efficient combination of phase development and construction, vehicle access, drainage, soil transportation, and closure should be established.

When sizing the filling phases, the first priority is to provide enough fill capacity to last until the next phase is constructed. Once the minimum size of each phase has been determined, the most economical size for each phase (based on the site's required fill capacity) can be determined.

Closure Sequencing

Closure sequencing does not often receive much consideration. When put into the proper prospective, closure sequencing should be evaluated in terms of economics, leachate minimization, and drainage.

The economic effect of various closure schedules presents two conflicting concerns: the time value of money and financial assurance. Based on the time value of money concept, it would be best to delay spending money on closure for as long as possible. The amount of financial assurance is based on the largest area of the landfill which will ever require closure, however. So delaying the cost of closure basically increases the amount of financial assurance which must be provided.

In terms of leachate minimization, it is generally best to cap portions of the site as soon as possible to limit the amount of infiltration which can cause leachate. Most landfills are designed to drain properly at closure. However, it is important that interim drainage be given adequate attention as well.

Are your landfill operations going as smoothly as you would like? Do you know what big projects are approaching and how you are going to complete them? The following list describes some of the sequence plans we have created for others. Perhaps you're landfill would benefit from having a set of "optimized" fill sequence plans.

Submitted by <%=company%>