Wastecon 99's Exhibitors Covered Landfill Managers' Concerns

Space concerns

CDM (Cambridge, MA), one of the several consulting firms at the Wastecon exhibit, described its innovative proposal to solve the landfill shortage of a large Asian city by building the landfill in the ocean.

Pulau Semakau is an island in-the-making off Singapore's southern shore. It literally will "form" the answer to the nation's solid-waste-disposal needs for at least the next 30 years, says CDM.

CDM has been at work for several years planning and engineering this mammoth project. Using inert ash and unburnable refuse for a base, Singapore is building what should eventually become a new 865-acre island.

According to the design team, as the offshore disposal site begins operation, Singapore is not only realizing the solution to a long-standing land-use and public-health challenge but also anticipating the promise of natural resource and recreational assets to come.

"This project is the linchpin of Singapore's comprehensive waste management approach," said CDM Project Manager Bob Burkard. "It's conserving developable land in Singapore and reclaiming land from the sea."

Housekeeping concerns

Landfill managers constantly are trying to improve their competitive position and operating efficiency, and many have turned to alternative daily cover to succeed.

About a half-dozen tarp manufacturers were among the ranks of ADC exhibitors. Of them, Tarpomatic was presenting its automatic tarping system.

Mike Slutz is vice president of the Canton, OH, company. He cited numerous testimonials regarding the system's performance, such as the one from the Cold Canyon Landfill (San Luis Obispo, CA), which—despite more than 40 inches of rain one winter—achieved 100% coverage of its winter working faces without having to fill over tons of mud.

Or, the Brook Sanitary Landfill. (Wichita, KS), which attested to Tarpomatic's ability to perform in 50-mph winds and 12 inches of snow.

Among system features enumerated by Slutz are:

- tarps fabricated to customer's equipment

- tarps up to 50 ft wide

- a 20-hp Kubota water coded diesel power plant

- automatic lay down and pick up of tarps, and

- an electric (over hydraulic) control center (wireless remote control available)

Pollution concerns

Landfill gas and leachate-management programs present problems often requiring special attention to achieve their technical and commercial objectives within budget and on schedule.

Several exhibitors at Wastecon '99 professed to having the design, planning, and managerial expertise needed. Among them, Soiltec, Incorporated (Dover, NH) also featured some of the equipment it produces to complement its "paper and pencil" skills. (For a description of its landfill gas manifold, click here.)

Other equipment produced by Soiltec includes leachate extraction-and-treatment equipment, landfill-gas utilization plants, SCADA remote-management systems, condensate-removal equipment, and landfill-gas flares.

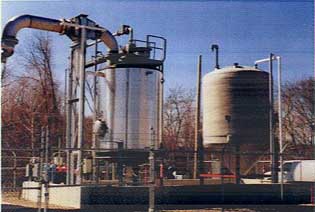

For handling landfill gas, EMCON/OWT (Andover, MA) was offering E-Vap, a double-barrel-action technology—controlling landfill-gas emissions and leachate as one.

Landfill gas extracted onsite is combined with air to power a specially designed burner. The hot-combustion gas is directed through the leachate, converting the leachate to water vapor along with vapor of VOCs present in the leachate. According to EMCON/OWT, the sealed system vents all off gases to an enclosed flare where they are thermally oxidized. Hydrocarbons become water and carbon dioxide, eliminating the potential for odors. Metals and salts found in the leachate feed remain with residual (concentrated leachate).

EMCON/OWT claims that E-Vap evaporates at least 97% of the leachate treated. The process leaves a small quantity of non-hazardous residue that can be recirculated to the landfill or solidified for landfill disposal.

E-Vap, says EMCON/OWT, has all its functions computer controlled and monitored 24 hours a day.

Edited by Paul Hersch